Hiber and WTS Energy form strategic joint venture for well integrity monitoring

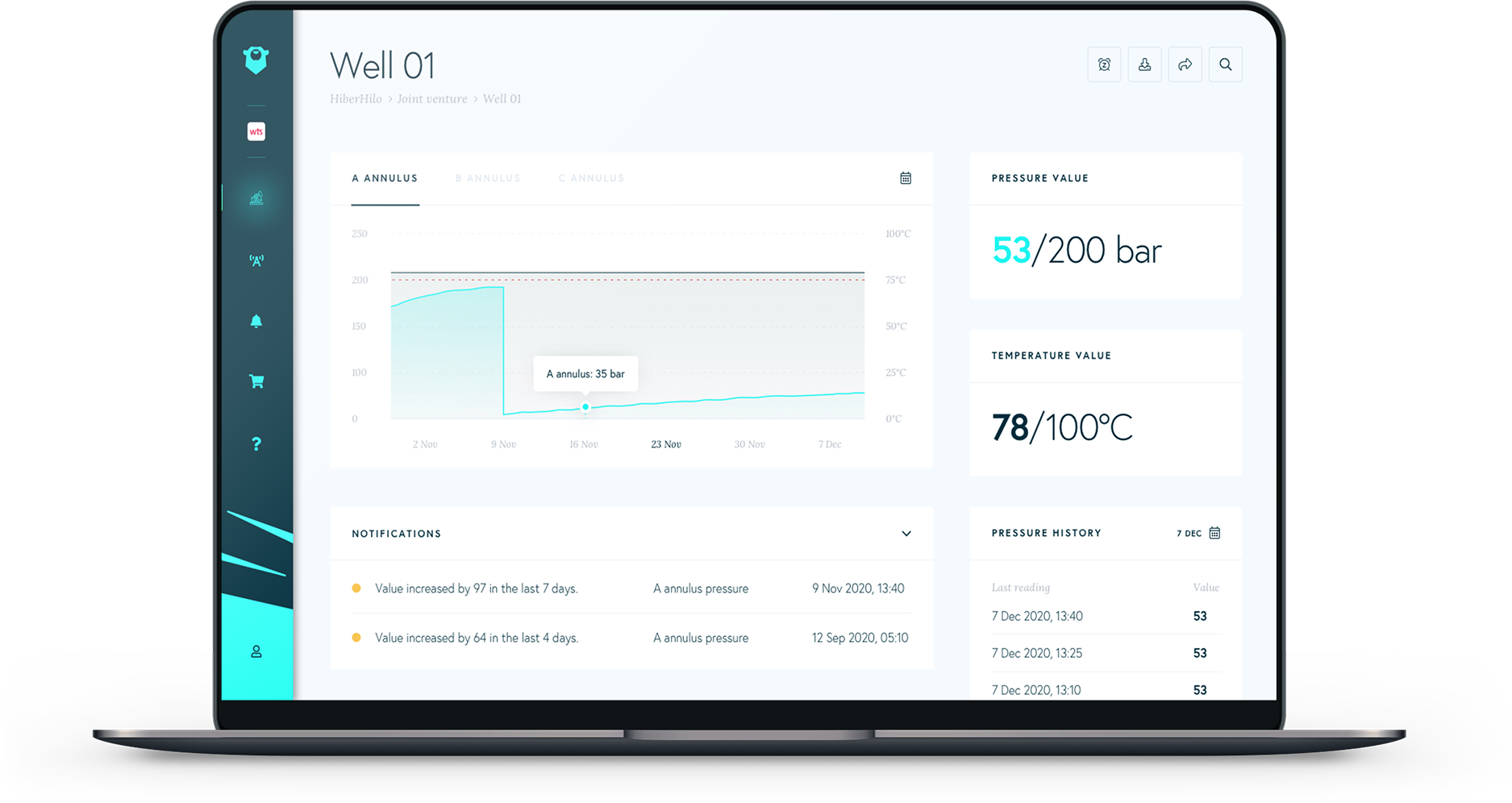

Industrial IoT as-a-service company Hiber is partnering with WTS Energy, the solution supplier in the international oil and gas industry, to roll out its well integrity monitoring solution globally. As part of a strategic joint venture with WTS Energy, Hiber has developed HiberHilo, an end-to-end IoT solution that makes well monitoring safer and more data-driven.

HiberHilo uses satellite technology to enable oil and gas companies to measure real-time well temperature and pressure for up to 250 remote and offshore wellheads within a radius of 10km. Hiber and WTS Energy will work together on the installation, service, and maintenance of HiberHilo.

With offices and 1,250 consultants in 18 countries across the world, WTS supports its oil and gas customers in their digital transformation. WTS aims to deliver the latest technological solutions to its customers, and has partnered with Hiber to provide HiberHilo across the industry.

“We are excited to launch this joint venture with one of the major international standard bearers in oil and gas,” says Coen Janssen, chief strategy officer and Hiber co-founder. “An oil or gas well blowout can be a disaster in terms of safety, environmental impact, and commercial impact. Wellhead monitoring can be complex, time-consuming, and expensive; HiberHilo provides an innovative and affordable subscription service to ensure continuous, satellite-based wellhead monitoring, even in the remotest locations.”

“At WTS Energy, we work in many remote locations and well integrity monitoring comes with many logistical challenges,” says Frederik Rengers, CEO of WTS Energy. “We are all in the middle of the energy transition and it is important to keep the oil and gas industry safe and protect the environment during this time. Technology like satellite-enabled well integrity monitoring of remote wells is a key to keep existing wells environmentally safe. What you measure improves!”

Comment on this article below or via Twitter @IoTGN