MEMS packaging and testing: Is this the next opportunity for OSAT companies?

More than half of MEMS packaging is done by OSATs and Yole Développement (Yole) estimates OSATs’ market share will continue to grow in the next five years. The MEMS volume augmentation, especially for RF applications, is making the MEMS business more and more attractive for OSATs, which have started to offer wider range of packaging solutions and tests, accordingly to automotive standards.

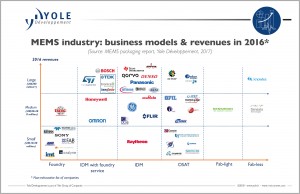

MEMS technologies have enabled performant, miniaturised, cost-effective and reliable sensors, some of them withstanding high temperatures and harsh environments. The diversity of MEMS devices and the different technologies involved in their manufacture have led to a complex but sustainable supply chain from design to testing involving foundries, OSATs and MEMS vendors. The MEMS packaging business is organised around five main families: inertial MEMS, environmental MEMS, optical MEMS, acoustic MEMS and RF MEMS…

To read the complete story click here.

Comment on this article below or via Twitter @IoTGN