The Internet of Manufacturing event summarised all of what is yet to come for Europe’s industrial sector

The second Internet of Manufacturing event in Munich just finished and it has a message to the European manufacturing community: get going with Industry 4.0 implementation projects beyond the hype currently surrounding the public discussions.

Below are listed a few aspects from the event’s agenda and afterwards we present the main takeaways that conclude the content and messages from the presentations, as well as the individual discussions of the delegates.

The Internet of Manufacturing most important aspects:

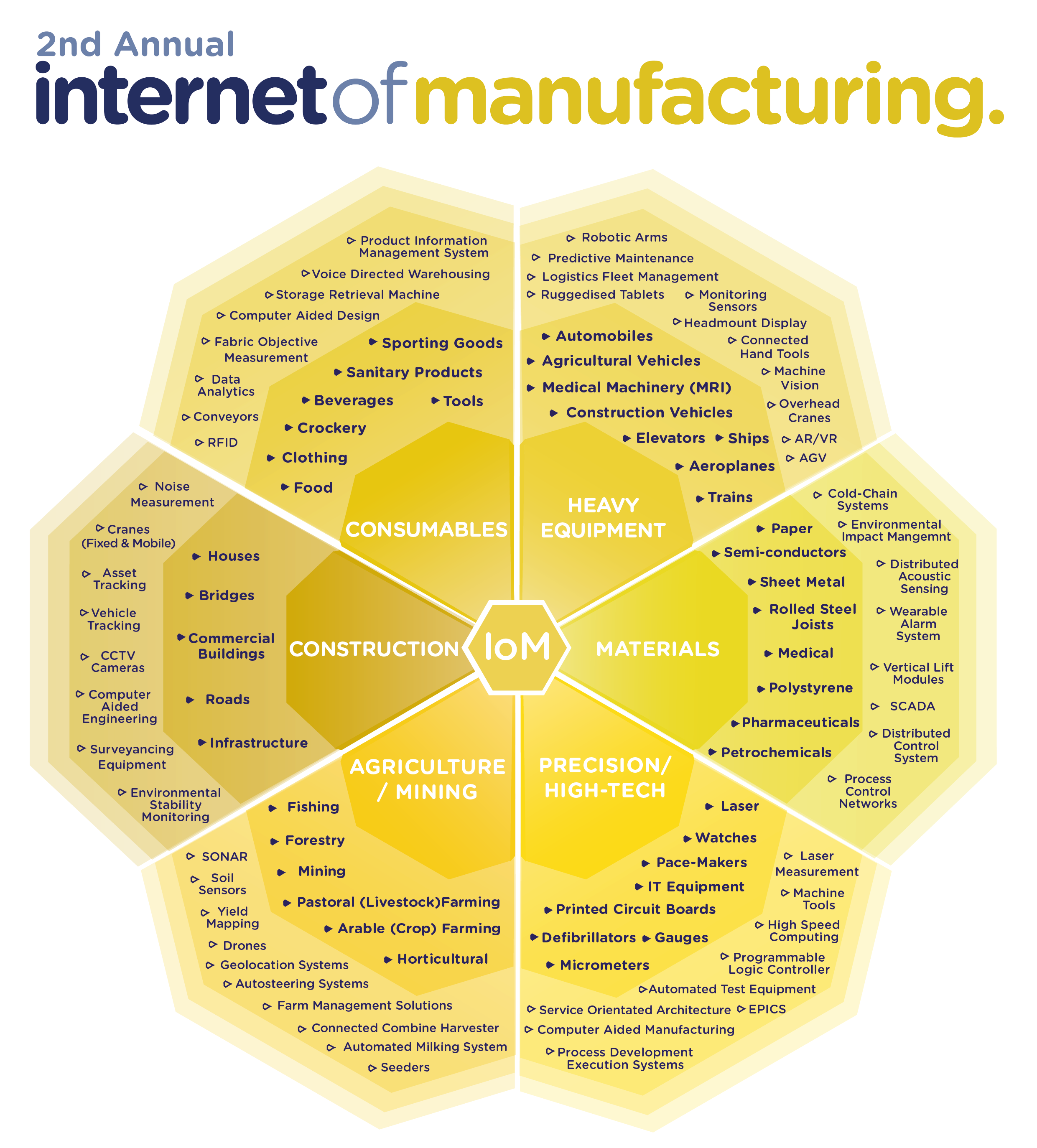

- Key characteristic of this event was the high level of focus to the industrial manufacturing area and the coverage of the biggest part of the production spectrum, such as heavy equipment, machinery, process and chemical production, software for industrial enterprises and ergonomics among others.

- Furthermore, the event encompassed cases from companies of all scales, ranging from big established multinational players, such as GE, SAS, Oracle and Pirelli, to the smallest start-ups making their initial steps in the smart manufacturing area, says Christina Patsioura, IoT, IIoT, Industry 4.0 research analyst, Beecham Research.

- The event’s agenda included presentation of use cases from different types of Industry 4.0 applications, from the most traditional of predictive maintenance to the more sophisticated ones with smart machine tools.

- And finally, the participation of other adjacent partner organisations, such as IIC and Industry 4.0 platform initiative, along with IG Metall, Germany’s big workers’ union, just to complete the picture.

Respectively, the following are the key takeaways of the event:

- Industry 4.0 has really penetrated in the minds of the affiliated professionals across all the major industrial verticals. Every person holding a relevant position in the industry acknowledges that they need to understand and practically proceed with actual projects.

- The Industry 4.0 agenda generates new internal divisions in companies, e.g. Smart Manufacturing, Digital Transformation department, as well as it subsequently adds to the existing position titles. Interestingly enough, we noticed some heads of IoT Labs, some chief digital officers, and so forth.

- Each industry has its specific characteristics that shape its specific needs in terms of how to adopt and integrate Industry 4.0 solutions. No matter how self-evident this might sound, it is not an easy task to adjust every type of solution to any kind of industry or business case. For example, reducing downtime is more crucial to the process manufacturing than to other types of production. So as Industry 4.0 projects are becoming all the more focused and profound, clear identification of the business case and the expected outcomes is crucial.

- Size and power of a company is not necessarily associated with successful Industry 4.0 positioning. Yes, indeed, many of the biggest players in the market have implemented projects and are quickly moving towards the so-called digitalisation of manufacturing, but quite a lot of them are also reluctant to proceed or they are concerned of how to leverage on their rather big pool of resources.

- Projects related to this very agenda are fit for companies that have achieved an adequately satisfactory level of operation and want to evolve further. For example, industrial companies that still struggle with issues of basic quality assurance for their products or safety of the workforce need better to focus on these priorities, as the market is moving fast.

- The future of workforce in the manufacturing area is of great interest to all the affiliated members of the industrial community, particularly the one active in the German market. Trade unions are working with companies, the government, the schools and academia in order to educate executives, employees, researchers and young students in accordance with the future labour needs of the industry. According to their beliefs, humans will be the epicentre of the technological advancements, as these are going to be assisting and not substituting them, while human factor is the one which is going to develop, maintain and control every technology in the end of the day.

- Security and ownership of data are of utmost importance for all the partners involved in current projects and constitute major issues for all those still considering to jump on the train in the near future. Organisations such as the IIC and the European Commission have made big steps towards simplifying the data-related regulatory issues, yet there are still more to be done in order to achieve a clear landscape for businesses and individuals.

- Stretching beyond that, data and security concerns are also proving to be a key defining factor for business decisions; for example, an OEM that decides to share his data with an IoT Platform vendor in order to integrate their systems, suddenly might realise an additional factor of exposure to risk for their company, its precious performance data and financial figures.

We at Beecham Research are convinced that our previous year’s “get real” campaign, regarding the need to be wary of inflated market forecasts and estimations is really paying off; people are interested in the real benefits and actual projects implementation steps, which need focus, hard work and imagination to come to fruition.

Last but not least, as we have been helping companies with identifying their way through the Industry 4.0 agenda, the observed big education gap that currently exists in both the vendor and the adopters areas has really been confirmed by this exceptionally interesting event organised by Vinelake. 2017 will probably be the year Industry 4.0 market achieves a higher maturity level.

The author of this blog is Christina Patsioura, IoT, IIoT, Industry 4.0 research analyst, Beecham Research

Comment on this article below or via Twitter @IoTGN