New version of PTC’s CAD platform introduces a renaissance in design

Brian Thompson of PTC

PTC announced the latest release of its Creo 3D computer-aided design (CAD) platform, which enables engineers to harness innovative design and manufacturing capabilities in one environment. Creo 6.0 introduces new capabilities in real-time simulation and extends the capabilities of Augmented Reality (AR) and design for additive manufacturing, along with numerous key productivity enhancements.

In the fast-changing world of product design, thousands of leading engineering and manufacturing companies rely on Creo to build better products faster. Engineers can drive innovation in their design process with embedded simulation and can quickly turn ideas into smart, connected products with IoT-driven design, all while collaborating in real-time with stakeholders around the world using integrated AR experiences.

“PTC is leading a renaissance in design. As companies work to bring their products to life digitally, they’re turning to Creo for real-time simulation, design for additive manufacturing, and more immersive, efficient, and secure collaboration using cloud-based augmented reality,” said Brian Thompson, SVP and general manager, CAD, PTC.

“For 30 years we’ve been a leader in the CAD market and have helped our customers differentiate in their own markets. Now we’re enabling customers to innovate further with new capabilities that support the new frontier of industrial design, and we are doing it all within the Creo platform.”

Leverage real-time simulation

The recently announced Creo Simulation Live offering gives real-time feedback on design decisions as they are made, allowing for simulation-driven design. Creo Simulation Live is a fast, easy-to-use tool that’s fully integrated into the Creo modeling environment and gives results in seconds as it runs in the background. Designers can now iterate faster, discover problems earlier, streamline their workflow, cut costs, generate more options, and get better products to market faster.

Collaborate with Augmented Reality

AR is improving the way engineers design and collaborate. This cloud-based technology offers an efficient way for engineers to share design information and collaborate securely with colleagues, suppliers, customers, and manufacturing partners. With Creo AR Design Share integrated into every seat of Creo, designers and manufacturers can iterate faster, make fewer prototypes, and engage in more meaningful design reviews.

Creo 6.0 includes new capabilities to make AR even more valuable with model and permissions management for up to 10 experiences and the ability to view models at full scale using smartphones, tablets, and HoloLens. AR experiences can now be easily accessed and launched using links, ThingMarks, and QR codes.

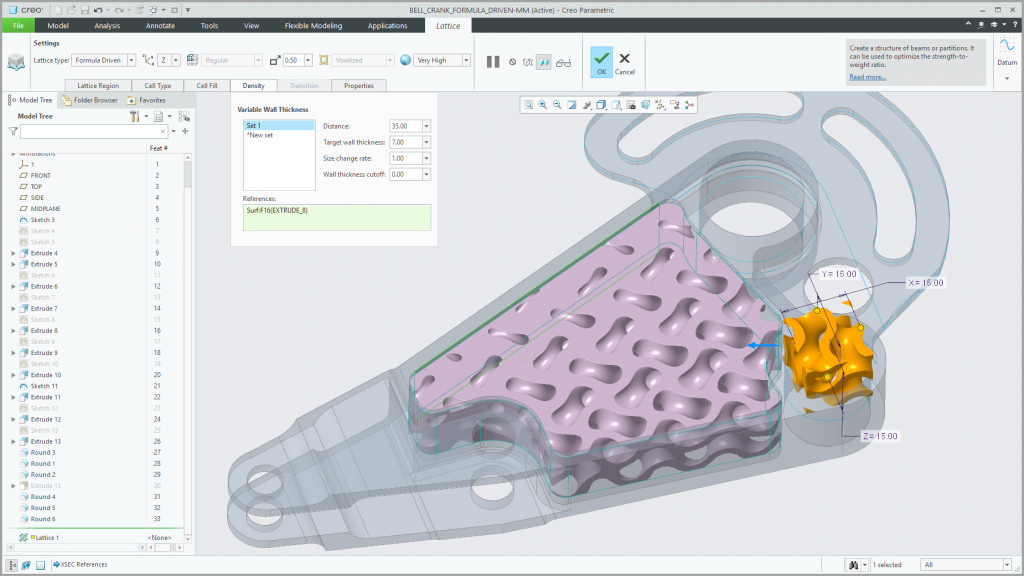

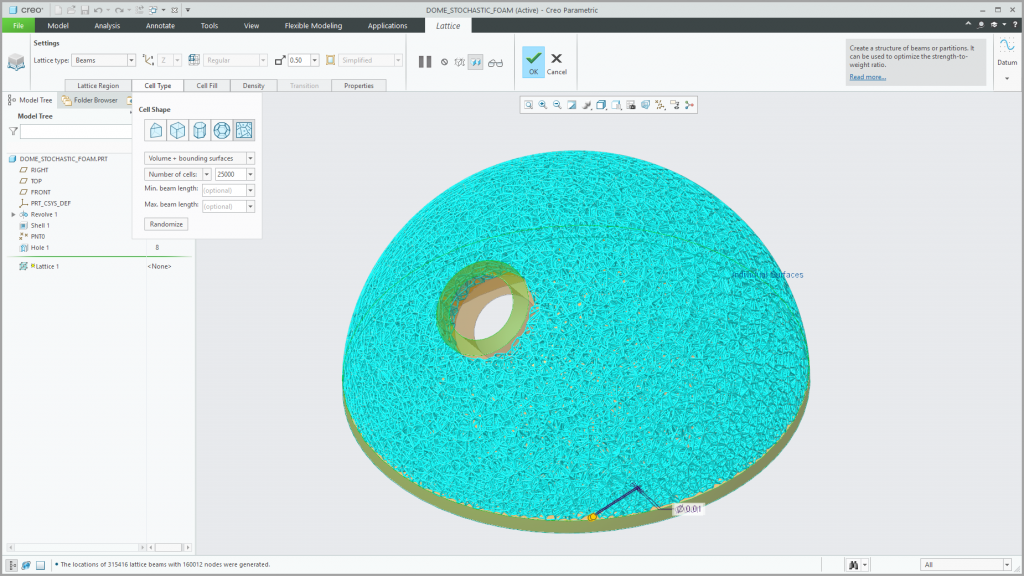

Design for additive manufacturing

Creo delivers the tools and connections needed to drive additive manufacturing, enabling an even broader array of manufacturing processes to be supported based on demand. Users can design, optimise, validate, and print check without leaving Creo, enabling them to reduce overall process time, tedium, and errors.

Creo 6.0 delivers even greater flexibility for designers by enabling them to build stochastic foam or conformal lattices, formula driven lattices, such as Gyroids, and define custom lattices using Creo geometry. Users now have the ability to analyse and optimise build orientation, enabling them to reduce print time, minimise support structures, or maximise tray utilisation. Creo 6.0 also introduces expanded support for 3MF.

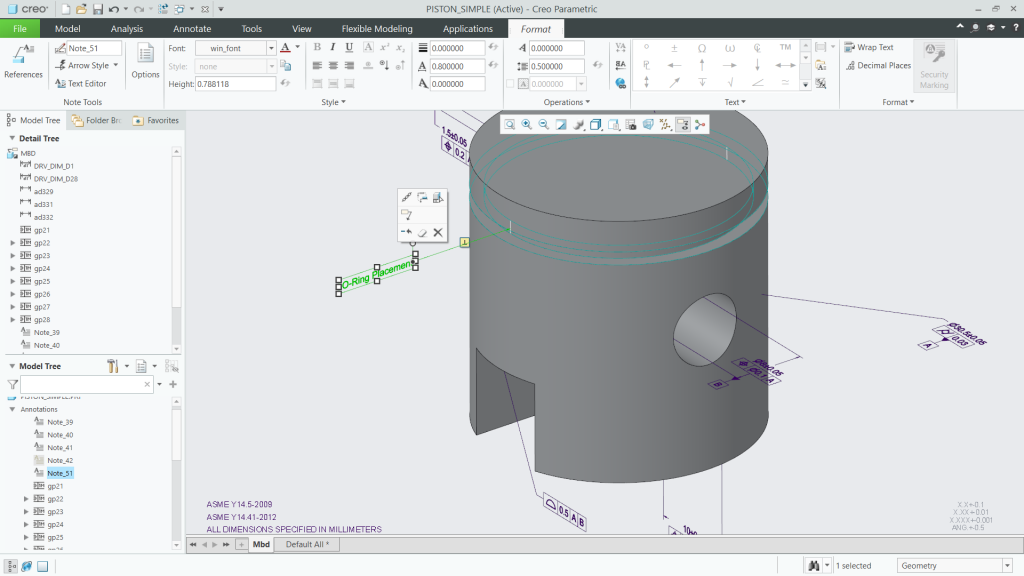

Improve productivity

Creo 6.0 provides increased usability, including an improved UI for a more efficient user experience with new mini-toolbars for creating and modifying features, modernised feature dashboards, and enhancements to the model tree. Other enhancements include improvements to advanced framework and intelligent fastener extensions, model-based definition, cabling, and core modeling.

Comment on this article below or via Twitter @IoTGN