Raising quality standards with the 4.0 Industrial Revolution

Yash Mehta

The progress made in technology has now spawned an era of digital transformation. The transformation was brought forth through digitisation as the analogue information was converted to digital data.

The increase in digital data has therefore enabled digitalisation, wherein technology is utilised to shape businesses and industries, says Yash Mehta. This phenomenon is now having a profound impact on the manufacturing sector and is labelled as the Industry 4.0, widely known as the Fourth Industrial Revolution.

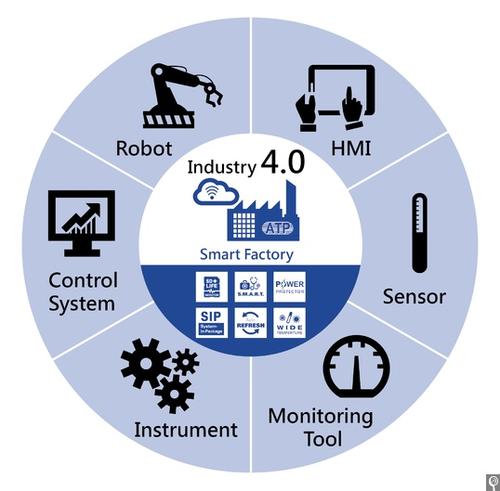

The Industry 4.0 is about bringing optimisation, efficiency and quality to the processes by incorporating intelligent cyber-physical systems. The Internet of Things (IoT), Artificial Intelligence (AI), Cloud Computing and Big Data Analytics are some of the technologies that are pushing forward this revolution. Kpmg estimated that the component market of Industry 4.0 could be worth over $4 trillion (€3.44 trillion) by 2020.

Quality control and management form one of the primary focus areas of Industry 4.0. Quality dictates the profitability of any product and even more emphatically in the current global scenario.

Today, people are increasingly becoming quality conscious and they don’t mind paying more for better quality and sustainable goods. This is particularly a pain point for industries because products are getting more and more complicated, especially in terms of the manufacturing aspect.

Besides, consumers expect agile and seamless purchase experience and delivery, as a result, manufacturers are facing the pressure to cut short the lead times in production in order to reduce time-to-market for products.

In a survey of executives, it was found that they ranked time-to-market as the greatest challenge in quality management followed by product complexity, globalisation and regulatory changes. Thus, quality improvement and monitoring are identified to be among the top industry 4.0 use cases.

Quality 4.0 has henceforth emerged as a term to signify the emphasis placed on quality in the era of Industry 4.0. It does not refer to a technology; rather, Quality 4.0 alludes to the improvement in the quality standards of production processes and products through Industry 4.0. This is done by improving the existing traditional quality management process, not by replacing them. The strategy has incentivised startups to provide solutions that address the quality demand.

Seebo is one such startup that looks to provide a SaaS platform for Quality 4.0 with predictive analytics. By creating a digital model of the manufacturing process, including quality control procedures, and then applying AI to the model and its real-time data, Seebo’s platform is able to generate a Predictive Quality Digital Twin, highlighting potential quality failures and their root causes.

Such solutions are easy to implement and make it immensely relevant for adopters of 4.0 technologies and strategies. Quality 4.0 is, therefore, about giving manufacturers a competitive edge and presenting them with unique opportunities and capabilities to drive innovation and revenue growth.

The reason for Quality 4.0

Quality 4.0 enables leaders to achieve quality objectives such as ensuring compliance, improving customer experience, improving product design and value and reducing operational risks. However, many are unaware of the Quality 4.0 use cases, and to strategise quality initiatives there needs to be clarity on what it entails.

LNS research has identified a use case on beer brewing in the US that implemented Artificial Intelligence (AI) and Machine Learning (ML) to eliminate batching problem due to quality issues. The brewmasters employed ML/AI model to alter the recipe and optimise batches to fine tune various factors that come into play while brewing beer.

This way, they removed the quality issues and were able to recover the lost production capacity quickly. Following are the key reasons to consider Quality 4.0:

Profitability

When ensuring quality becomes the focal point of a manufacturing process or of a product, it ultimately yields more profit. Quality leads to more satisfied customers, resulting in brand differentiation that leads to customer retention and greater profits. In addition, wastes can be reduced with an effective quality process in place. Currently, many companies rely on traditional quality management processes and technology which causes a financial drain on them.

Improved regulatory compliance

Compliance is an important aspect of quality management. It includes adhering to various requirements. Quality 4.0 ensures compliance of products, processes and services by automating the procedure. With the help of analytics, alerts regarding potential regulatory compliance breaches can be issued automatically. Transitioning to Quality 4.0 is easier for companies since most companies already have pre-configured compliance requirements and QMS solutions in place.

Adoption of quality management systems

QMS provides a central platform to manage activities pertaining to quality, such as ensuring compliance, analytics, collaboration etc. Currently, it is reported that only 21% of the industries have adopted QMS, as their core processes are yet to be streamlined and integrated. Therefore, Quality 4.0 provides an avenue for harmonising processes to improve efficiency and effectiveness of operations.

How to achieve quality 4.0?

LNS research has identified 11 major components of Quality 4.0 which the companies can take as a guideline to adopt 4.0 quality standards. These are- data, analytics, connectivity, collaboration, management systems, app development, scalability, compliance, culture, leadership and competency.

Companies should appropriately assess where they stand on each of these components and improve upon the areas in which they lag behind. In addition, enterprises that have already laid a quality management ecosystem can improve their quality standards by the innovative adoption of 4.0 technologies for methods, such as remote monitoring and maintenance, Predictive Analytics etc.

While Predictive Analytics enables to identify patterns in the data and suggest corrective actions to ensure performance quality, the capability can be extended to provide continuous remote monitoring to achieve the same.

The bottom line

Quality management has a significant role in building the core competency of any enterprise. Quality 4.0 is, therefore, a strategy to improve the traditional quality management and is a means to bring a revolutionary change to business operations. By reducing costs, optimising processes and thereby increasing efficiency, Quality 4.0 enables enterprises to be the key drivers of innovation and provides them the opportunity to stand out in a heavily competitive market.

The author of this blog is Yash Mehta an IoT and Big Data Science expert. He is an award-winning writer appearing in many publications

Comment on this article below or via Twitter @IoTGN