Top Industrial IoT trends from ‘IIoT survey – 2017’ – Part 1

Recently, we conducted a survey to understand the current state of ‘Industrial IoT (IIoT)’ and its future outlook. The objective was to forecast industry trends and business sentiments.

This study was conducted over the period of April 2017 – June 2017. We interviewed 350+ individuals from wide array of industries including Manufacturing, Agriculture, Industrial Machines and Equipments, Logistics, Aerospace, Chemical/Petrochemical, Oil & Gas, Consumer Goods, Electric Power etc, says Ayush Jain CEO, Mindbowser.

This survey was conducted by Mindbowser. (Download the survey here)

Here are the major findings from this survey:

1. Industry readiness for IoT

Industries seem to understand the importance of IoT solutions and their impact on business. 64% Respondents said they are either engaged in or planning an IoT project in next 1 year. While, 36% respondents do not have any plans to implement IoT solutions at least for next 1 year. (Among these, 83% still feel that they need to increase the efficiency

of their machines)

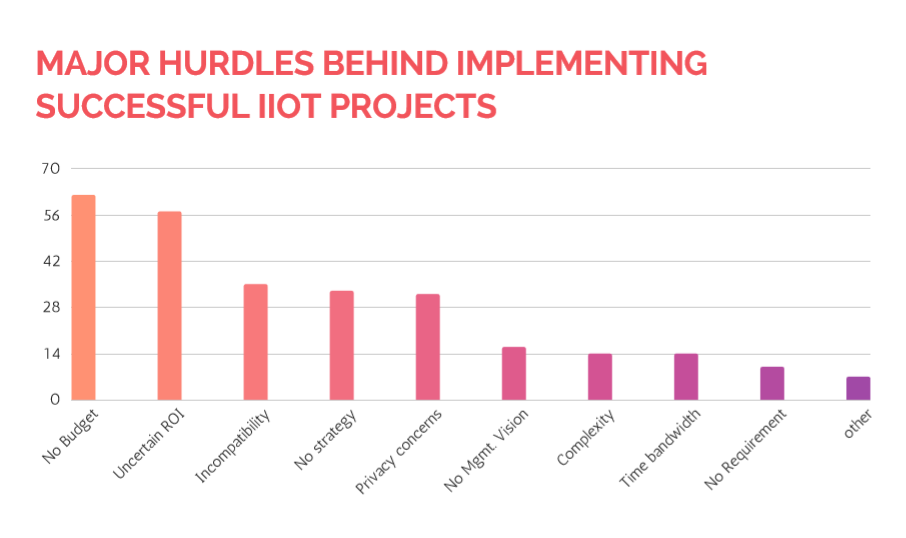

2. Major hurdles behind implementing successful Industrial IoT projects

You’d ask, if so many companies understand the importance of Industrial IoT then why there are only handful of companies adopting it? Well, it turned out there was not a single answer but a pile of hurdles that companies were facing.

Here’s what we found:

Lack of budget – 63% companies said they don’t have enough budget to implement IoT solutions. This might be because they are are not allocating enough funds to innovate and explore new opportunities that IoT brings.

Uncertain ROI – As the famous saying goes – as you sow, so shall you reap, companies look for certainty about ROI on their valuable resources if they are to invest in a major IoT project. And we don’t blame them either, majority of Industrial IoT initiatives demand heavy investment from its beneficiaries and returns are not guaranteed every

time.

Incompatibility of existing machines – Well, this is a typical one. If your existing machines are from the ‘stone age’, latest technology might not support them. So instead of going through the trouble of replacing or upgrading existing machines, companies comfortably choose to avoid the integration of IoT altogether.

No clear strategy – Well begun is half done. In many cases, management underestimates the benefits of Industrial IoT and overestimates reasons why they should not go for it. Lack of management vision emerged as one of the top 5 hurdles to implement IoT solutions. So having a clear strategy or even a small IoT project can ensure your company’s agility.

Time bandwidth – “We do not have any time for new initiatives this year, we got too much on our plate” Sounds like a common phrase? Because it is ! Many times companies truly have a time crunch and cannot afford to take on another major project while focusing on core operations. So this makes it one of the major hurdles to get started with Industrial IoT. The solution? May be they need to find more SPACE for initiatives which might be a trend right now but will become mainstream in future.

No requirement – More than a hurdle, it’s a reason why some of the companies do not even consider to adopt IoT solutions. In our survey, 10% companies said, they do not see the requirement to integrate any kind of IoT solution in their operations. So they decided to stay away from any commitment towards it.

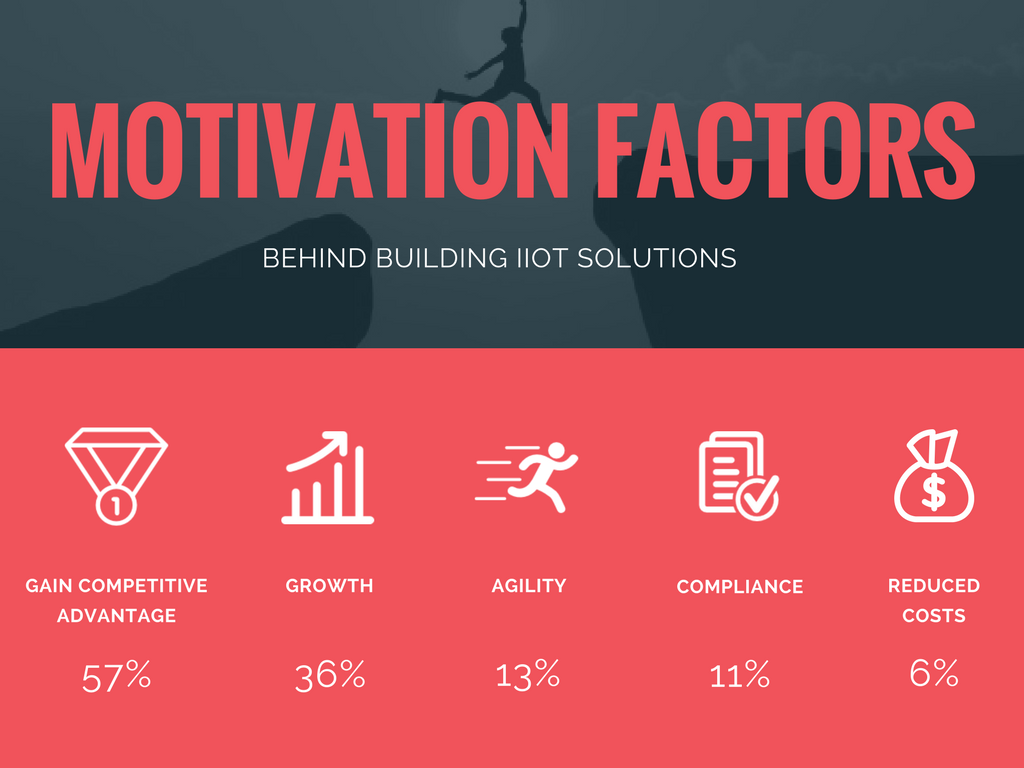

3. Motivation factors behind building IIoT solutions

We have seen what are the hurdles behind building Industrial IoT solutions. Now, let’s have a look at some of the catalysts that motivate companies to implement IIoT solutions.

Gaining competitive advantage – Gaining competitive advantage emerged as a leading factor for companies to consider building IoT solutions. Let’s consider data mining for example, whether it’s manufacturing or logistics, businesses are sitting on a gold mine of data. Only now, thanks to the Industrial Internet of Things, can companies

unleash it to gain competitive advantage.

Growth – IoT is now driving the next level of digital adoption not only across consumer industries but also in manufacturing, supply chain and other areas. This in turn is resulting in operational excellence, discovery of new revenue models, enhanced employee engagement and most importantly, superior customer experience. This

propels the company growth to the next level.

Compliance – Companies need to follow compliance mandates to become eligible for certain type of projects. These mandates have a range of objectives including: protecting consumer and business interests, spurring innovation, promoting safe business practices and modernising infrastructure to meet future demands. Industrial IoT provides

multi-billion dollar opportunities for vendors across industry value chains. So compliances play a key role in IoT adoption.

Reduced costs – Someone might ask how a costly adventure like Industrial IoT can reduce operational cost. The answer is, by increasing efficiency! How? IIoT solutions help companies with energy management, finding actionable data, predicting asset failures, identifying new revenue streams and many other ways to decrease costs and increase profit.

4. Satisfaction level with current Industrial IoT solutions

19% respondents seem to be very satisfied with their current IoT solutions while 9% are fairly dissatisfied. Almost 17% people said they don’t see any clear results as of now. While 42% respondents are happy with existing IoT solutions and just with few improvements, they are good to go.

5. Areas of improvement in IIoT solutions

Ayush Jain CEO, Mindbowser

Those who have implemented IoT solutions in their organisations think there is still a scope of improvement. Majority of respondents (71%) believed that Industrial IoT needs better alignment with revenue generation. Also, 42% people said they need better internal connectivity between their machines. Almost 37% companies admitted that their system requires a technology upgrade. Human resource training was lacking in 27% of the cases.

These are Top 5 trends from the survey. Check out the part-II of this report and see what are the other trends that will have significant impact on Industrial IoT.

The author of this blog is Ayush Jain CEO, Mindbowser

About the author:

Ayush has been involved in building solutions for multiple industries as an architect and then as a consultant. He expertises in building simple solutions for complex problems. He is a marketer by nature and keeps himself updated with latest technology trends.

Comment on this article below or via Twitter @IoTGN